Size from 60-90kg Pockets

A large number of configurations are available

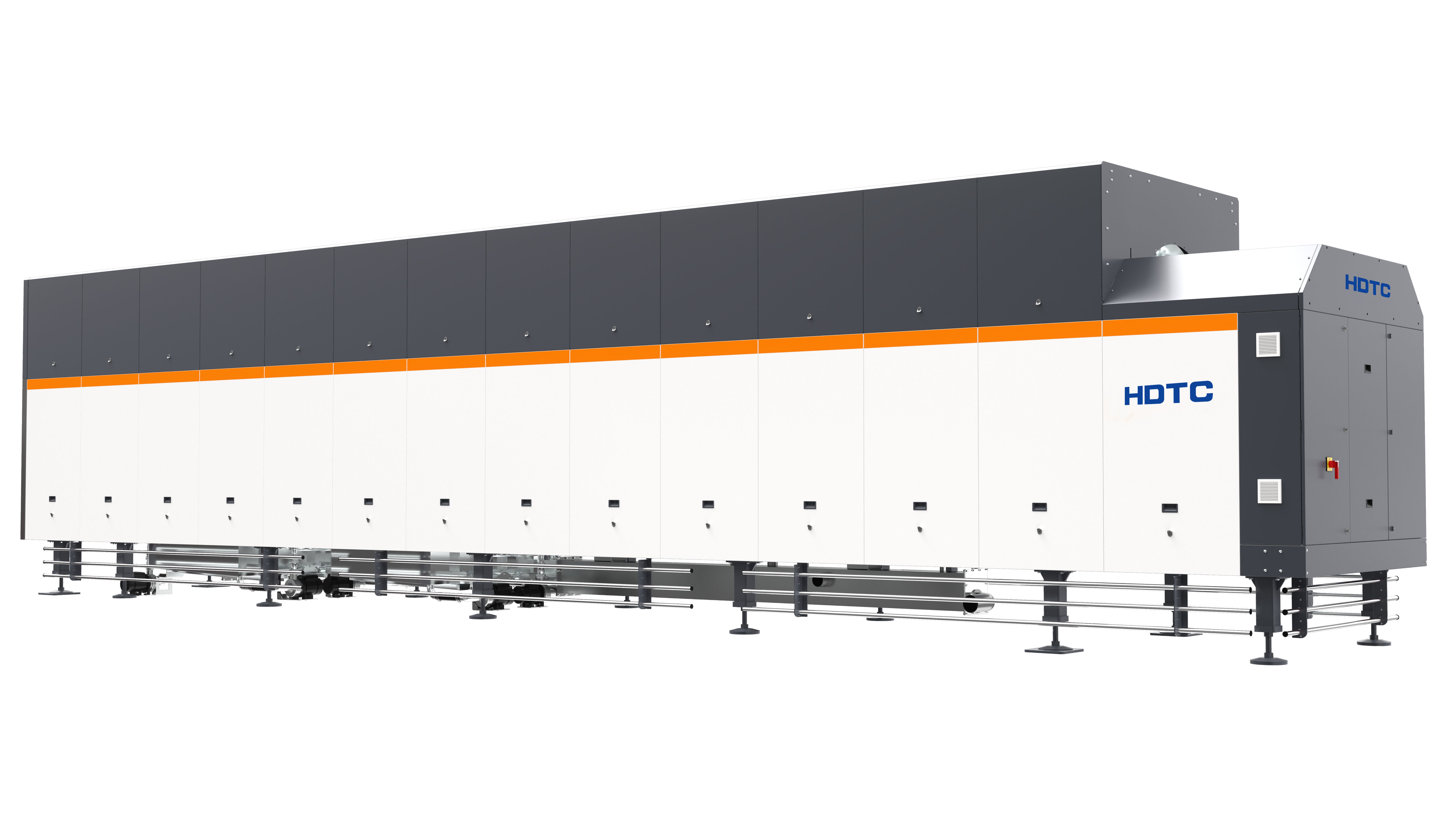

- CBW

- Press

- Shuttles

- Dryers

- Extractors

Models running in Australia available for viewing.

Gas or steam

- Available in 2 or 3 roll configurations.

- Roll widths of 3m, 3.3m, 3.5m and 4m.

- Direct drive to rolls cutting down on maintenance and downtime.

- High thermal efficiency.

- Sheet corner flattening device.

- option of infeed belts or fed directly from feeder.

- High grade PLC and inverters.

- Automatic calibration system to reduce mechanical stress and improve the life of your padding.

1. Fast speed

2. Smooth operation – low discount rejection rate, extremely low probability of cloth being blocked, even if it is blocked, it can be taken out within 2 minutes.

3. Good stability – good rigidity of the whole machine, high precision of transmission parts, and all parts are matched with high-quality imported parts.

4. Labor saving – automatic sorting and stacking of bed sheets and quilt covers can save labor and reduce labor intensity.

Manual feeding system with vacuum for great quality on sheets, doona covers, small piece and table linen.

Bag handling and storage systems, tailor-made according to your specifications:

Using Omron Control Systems

- – Bag system for soiled linen, including loading stations, lift, unloading into tunnel washers, etc

- – Bag System for clean linen, or at the clean side. Loading station(s) for receiving the linen from the dryers/shaker and storing with unloading positions etc.

New towel folders

- Automatic identification and sorting of all kinds of linen (bath towel, floor towel, towel, etc.), and automatic adjustment of procedures

- Air blast folding for faster production

- Currently in stock